Last time you learned about our BIG Product, Bow-Tie PM Fiber – this month, it’s the turn of the BIG Application. So let’s answer five simple questions:

1. What is a gyroscope?

2. What is a fiber optic gyroscope?

3. What makes a fiber optic gyroscope better?

4. Why does a FOG need Bow-Tie PM fiber?

5. What are the key PM fiber design elements?

Put simply, a gyroscope is a device that measures rotation. So, by using a  gyroscope, you can find out where something is pointing (e.g. an aircraft) or how level it is (e.g. a hovering helicopter, a high-speed train carriage or even a pair of binoculars). This is why gyros are used to help navigate ships, aircraft and even some land vehicles and in systems used for automatically stabilizing things.

gyroscope, you can find out where something is pointing (e.g. an aircraft) or how level it is (e.g. a hovering helicopter, a high-speed train carriage or even a pair of binoculars). This is why gyros are used to help navigate ships, aircraft and even some land vehicles and in systems used for automatically stabilizing things.

To be effective, you need one gyro for each degree of freedom (or ‘axis’) in which the ‘platform’ can move. Aircraft, for example, can move in three dimensions – so need three gyros to cover roll, pitch and yaw.

Traditional gyroscopes have been around for more than 100 years and work on the ‘spinning mass’ principle. Those of you who had a gyro top as a child, or have played with one of those wrist-strengthening balls will recall that when you spin the rotor, the gyro gets a mind of its own and wants to remain upright? Well it’s the force that the gyro exerts trying to right itself (aka ‘gyro torque’) that can be used to determine how far you have tried to rotate it.

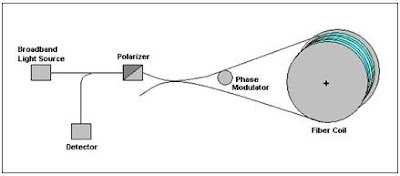

A FOG achieves the same result, but using polarized light and something called the Sagnac Effect. The Sagnac Effect states that if light travels simultaneously in both directions around an enclosed optical system and the optical system experiences a rotation, the light will undergo a Doppler-Shift (remember how police sirens change pitch as the car speeds past you?…same thing) with the result that the two beams will recombine out-of phase, creating interference. If you analyze this interference, you can find out the degree and the rate of rotation. In essence, a simple FOG looks a bit like this:

The true benefit of FOG over a traditional, spinning-mass gyro is that it has no moving parts – no moving parts means nothing to wear out and nothing to service. As a result, FOGs are tougher, more reliable and demand far less maintenance. In fact one Fibercore customer found that the military could use one of their systems for an average 30 times longer before repair, simply by switching from conventional gyros to FOG. Another advantage of FOG is that it is ready to work immediately, whereas a spinning-mass gyro can take up to 30 seconds to spin-up and stabilize. 30 seconds might not seem that much – but those of you old enough to remember the Cold War, will also remember that we would only have had three minutes to wait from detection to destruction. Right up until the early 1980s – 30 seconds was a long time!

The optical fiber in a FOG enables a very long optical path length to be confined into a small volume and so magnify the small phase shift caused by the Sagnac Effect – and the longer the path length, the more accurate the FOG. Satellite manufacturers often ask for long lengths of continuous fiber, sometimes up to 5,200 m lengths of HB1500G variants – this is because the fiber is used in the very accurate FOGs used in satellites launched by the European Space Agency (ESA) that make sure that the solar cells are always pointing at the Sun. And if those solar cells stop pointing at the Sun, the satellite dies – so I guess we play a pretty important part in ensuring the success of ESA missions!

The fiber used in FOGs needs to preserve polarization because, in order to generate stable interference, two light waves have to have the same orientation – if they crossed at right angles, they wouldn’t even know the other one was there! Typically, people want to get the longest optical path length into the smallest possible space and this leads to small diameter coils with multiple layers – demanding lots of birefringence (short beat-lengths) to make sure that the micro-bending created within these layers does not counteract the stress inside the fiber (see 5-Minute Expert #3), high numerical apertures to ensure that the fiber continues to guide strongly in these small coils (see 5-Minute Expert #1) and reduced fiber diameter, to improve lifetime and save space (see 5-Minute Expert #1). All of which go a long way to explaining our current development direction of ultra low-profile, ultra-high birefringence Bow Tie PM Fiber.

Fibercore’s product range can be found at http://www.fibercore.com/